Juneau has the wrong kind of wind, and the cost to build roads that would enable construction is so high that the cost of power would not compete with other viable options.

Mostly used to make renewable energy projects more cost-effective, hydrogen production is expensive when compared with using interruptible loads to manage surplus energy, but it may be useful in the future when new renewable energy projects are developed.

This is a good complement to Juneau’s existing generation sources, but uncertainty in the fuel supply and the cost of building and maintaining fuel storage and handling equipment make it not cost effective compared with hydroelectric projects that could be developed.

Juneau specializes in rain more than sun, so the area needed to produce a meaningful amount of electricity is huge, and the high cost of land in Juneau makes the price per kilowatt-hour of solar energy too high to be worth pursuing at this time.

It may seem surprising when you smell the landfill, but we don’t produce enough trash or landfill gas to cost-effectively build a plant that produces electricity.

Because the ocean is hard on equipment and the potential to negatively impact wildlife around Juneau is high, we don’t see Juneau as the right testing ground at this time for this technology.

Juneau gets a fair share of windy days, and the strongest winds occur in the winter when we need the most electricity, so AELP hired a consultant in 2008 to examine the feasibility of wind energy in Juneau. It turns out that not all wind is created equal when it comes to generating electricity.

Wind turbines use blades shaped like an airplane’s wing, so when air flows over the blades, they generate a force that causes the turbine to rotate, much like when air flows over an airplane’s wing and provides lift. The lift that an airplane wing can create varies with the speed and smoothness of the air going over it, so as the plane slows or the air gets turbulent, it is harder to keep the plane flying smoothly. The same is true of a wind turbine’s blade: it needs consistent wind to spin efficiently and when the winds are turbulent, they need to be shutdown to prevent damage. If you think about the gusty wind that Juneau gets, you can imagine that the wind turbine would frequently see those turbulent conditions and would therefore remain idle for long periods.

Construction would present another challenge for wind energy in Juneau because utility-scale wind turbines are huge, and the locations near Juneau which are most suitable for a turbine are on top of ridges with no road access. Since the wind turbine and tower parts are too large to be lifted by helicopter, construction of the turbine would require building a road to the top of a ridge -- and the roads would need to include many switchbacks to accommodate the length of tower parts and turbine blades. The requirement for a road narrows the number of potential sites to locations outside of Inventoried Roadless Areas of the Tongass National Forest and, more importantly, raises the cost of construction to the extent that the energy generated would be significantly more expensive than building another hydropower project.

Below is a link to more information on wind energy:

https://www.energy.gov/eere/wind/how-do-wind-turbines-work

Hydrogen comes up with electric utilities largely as a way to make renewable energy projects more affordable by increasing utilization. For example, in many communities in Western Alaska with wind farms, there are times when the wind turbines provide more power than the community can use. The thinking goes that if those communities could create hydrogen anytime the wind turbines were generating more electricity than needed, then the hydrogen produced could be stored and used later to generate electricity with a fuel cell (or be used in some other way), which could bring in revenue to help make energy more affordable overall.

There are two main challenges in making this work. First, additional equipment is required to make hydrogen and then store it for use. Second, every time you convert energy from one type to another, the product you get at the end has less energy than you started with because you can’t be 100% efficient. That means each kilowatt-hour of electricity generated with hydrogen from a fuel cell is more expensive than each kilowatt-hour used to create the hydrogen to begin with. For this reason, communities with excess wind tend to focus on using interruptible loads, like electric-thermal storage heaters that can be turned on and off as excess wind power becomes available. Using interruptible loads means there is less energy wasted when converting energy from one form to another.

In 2005, AEL&P explored using hydrogen as a way to get value out of surplus hydro generation. However, like the example with wind farms in Western Alaska, providing electricity to interruptible loads was shown to be a more efficient use than creating and storing hydrogen. This was in large part because it took 2.5 kilowatt-hours to create enough hydrogen to generate 1 kilowatt-hour of electricity in a fuel cell. That said, it remains a compelling concept to use hydrogen for capturing energy that might otherwise go unused, particularly because in the future it may not be possible to find a suitable interruptible load, the cost for equipment to produce the hydrogen is going down, and hydrogen may become a more common transportation fuel.

For more information about hydrogen production, please visit the following link: https://www.energy.gov/eere/fuelcells/hydrogen-production-electrolysis

Biomass is a catchall term for just about any type of biological matter that may be converted to a usable form of energy, the most familiar form of which is wood burned to generate heat. Other forms of biomass include wood chips or pellets, algae, municipal wastewater biosolids, agricultural residue, etc. Most uses of biomass for energy involve combustion, but some alternative technologies can convert biomass into a gas which can be used to replace natural gas or propane.

One unique source of biomass in Juneau is used by the Alaskan Brewing Co. They burn spent grain left over from the brewing process in a specialized boiler to make steam, which is used for heat, industrial processes and to generate a small amount of electricity in a steam turbine. Using the spent grain in this way lets the brewery convert a waste product that it would otherwise pay to dispose of into heat that it would otherwise have to produce with heating oil. Adding the steam turbine also helps reduce the amount of electricity the brewery purchases from AEL&P.

In a large-scale version of what the brewery does, AEL&P’s parent company, Avista, also operates a biomass-fueled steam turbine at a plant in Kettle Falls, WA. There they generate electricity by burning wood waste from a neighboring mill and waste from logging operations. A number of years ago, AEL&P looked at constructing a biomass plant to generate electricity in Juneau. A benefit of using biomass for electricity in Juneau is the potential to help diversify local generation resources to make the system less susceptible to fluctuations in precipitation. The ability for biomass to provide that benefit depends on having: a reliable, affordable source of the woody material, high-volume dry storage for the fuel, a way to deliver fuel from the storage to the combustion unit, a way to manage ash, and a location which wouldn’t impact local air quality. Juneau does not have a mill or active logging operations, so AEL&P’s analysis showed that when you add up the cost and complexity of barging fuel from outside of Juneau, building a large enclosed storage facility, and operating and maintaining a complex fuel-handling system, the price to build and operate a biomass generating station could not compete with the cost of hydropower.

Some experimental biomass technologies may make sense in the future, especially if they apply the concept used by the brewery to make use of a waste product. For example, Juneau currently uses a great deal of heating oil to dry wastewater biosolids, which are then shipped south to be dumped in a landfill in Oregon. Emerging technology may prove capable of turning those same wet biosolids into producer gas and fuel oil. On a similar vein, while Juneau doesn’t have a mill, the community does produce some urban wood waste that could potentially be used in a wood gasification generator – a small, experimental unit was tested in Hoonah in 2014, and as of 2019, the Yukon government is funding tests of similar, more advanced units.

More information on biomass here: https://www.energy.gov/eere/bioenergy/biopower-basics

Solar PV modules generate electricity when sunlight hits a specialized, layered semiconductor. The percent of solar energy converted to electricity is typically 14-20%, which is not very efficient. If you have a large tract of land which receives a lot of sun and is close to a transmission line, then the sun can provide a cost-effective source of alternative energy.

The most efficient solar cells require direct sunlight to generate significant power. Think of it like a cloudy versus sunny summer day in Juneau. If it’s cloudy, you may need to wear sunglasses, but you will not get a sunburn nearly as quickly as you would in direct sun. Solar PV is a bit like this. If it’s cloudy, they will have full voltage, but without direct sunlight they can’t get generate full power.

Like many folks with remote cabins in Southeast Alaska, AEL&P uses solar in small, remote applications where regularly refueling a diesel generator or building a power line is not cost-effective. On a community-scale, though, the technology does not make great sense for Juneau. In addition to the fact that Juneau is not very sunny, solar PV is not very energy dense – it takes up a lot of room, and Juneau doesn’t have a lot of extra land not being utilized. For scale, if AEL&P built a solar array to cover the area bordered by Egan Drive to the south, Mendenhall Loop Road to the east, Back Loop to the North, and the Mendenhall River to the west (i.e., about half of the Mendenhall Valley), the annual energy produced by that array would be less than half of what Snettisham produces each year.

More information on solar here: https://www.energy.gov/eere/solar/articles/solar-energy-technology-basics

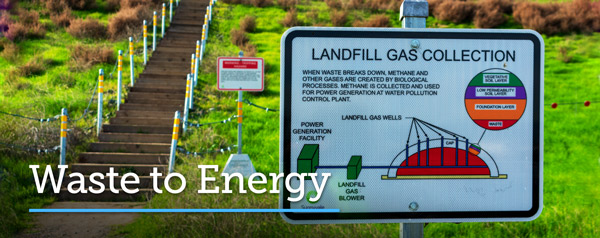

If you’re driving down Egan and occasionally get a whiff of the dump, it can feel powerful. There is a lot of organic material that winds up in the landfill, and as that material gets buried, anaerobic bacteria start to break it down. “Anaerobic” means “without oxygen,” and a byproduct of that anaerobic digestion of trash by bacteria is methane. Other gases are produced, too, like hydrogen sulfide, which helps explain the smell. In some areas with much larger volumes of trash entering their landfills, methane is captured from the landfill and used to generate electricity either by burning it in an internal combustion engine generator, or by using it to power a fuel cell. In Juneau, gas is collected and flared off because the CO2 that remains when methane is burned is a less potent greenhouse gas. There is not a central gas collection system and, even if collected, there is not enough gas to make it economical to use for electricity generation. Also, with the landfill having a limited lifespan, any electricity project developed would see diminishing returns as methane production decreased over time.

As an alternative to collecting and burning landfill gas, some areas utilize the waste heat from incinerating garbage to generate electricity with steam turbines. Air permitting regulations play a major role in determining whether a waste to energy project that relies on incinerating garbage can be successful. These plants also need a sizeable volume of garbage to ensure the plant can produce enough electricity to be cost-effective. For better or worse, Juneau does not produce enough waste or landfill gas to cost-effectively generate electricity with it.

More info on waste to energy here: https://www.energy.gov/eere/bioenergy/waste-energy

In the context of electricity generation, “hydrokinetic” is used as a catchall for generating electricity with technologies other than “conventional” hydropower projects. Types of hydrokinetic sources are those that use tidal currents, wave energy, or devices that are submerged into a river and rely entirely on natural stream flow. The most relevant of these to Juneau are tidal generators. We experience tremendous tidal fluctuations, and the energy available in the twice-daily ebb and flow could eventually produce an abundance of electricity with the right technology.

The technologies under development often look like underwater wind turbines, but the increased density of water means underwater turbines can be smaller than their above-water counterparts and produce the same amount of power. The saltwater wreaks havoc on mechanical equipment, and mechanical equipment can similarly wreak havoc on marine life. With abundant marine life around Juneau, AELP has not seriously pursued tidal generation because more conventional hydropower can be developed with far less environmental risk.

One exciting hydrokinetic project in Alaska is located on the Kvichak River near Igiugig. A company called Ocean Renewable Power Company has worked with the community and electric utility in Igiugig to develop a generator that sits on the riverbed, generating electricity from the natural flow of water in the river. KTOO put together an update on this project in 2019 (https://www.ktoo.org/2019/06/18/village-of-igiugig-one-step-closer-to-replacing-diesel-electricity-with-hydrokinetic-system/). One of the major components of the work to investigate viability of this technology was to study interactions with salmon moving upriver. With a bit more study, this technology could offset diesel generation in many remote communities in Alaska.